Products

Industry Focused Prodcuts

Yiga-P® IDLERS (PATENTED)

Improve Safety

▪ Less Change outs / Idler Changes

▪ Lower human interface / Lower Manpower requirement

▪ Less conveyor stoppages/down time

▪ Less risk of belt damage

Save Money

▪ Save maintenance costs

▪ Save operating costs

Improve system availability

▪ Fewer breakdowns

Industry Focused Prodcuts

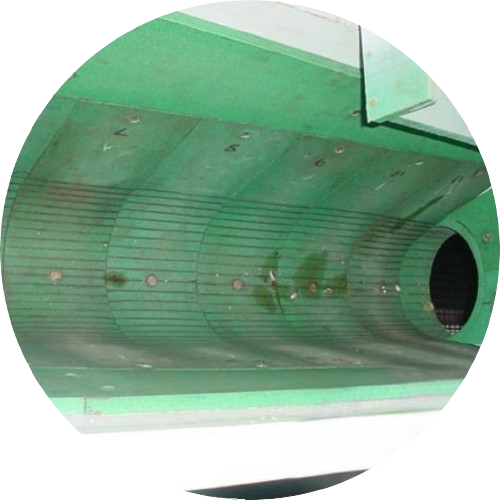

TUBE CONVEYOR IDLERS

▪ These idlers are used in tube-conveyors applications.

▪ The biggest advantage of these idlers is the fact that they cannot cut the belt. Similar

idlers produced from steel develop sharp edges and will eventually cut the belt.

▪ Thousands if these idlers are also used as guide idlers to keep the belt from sliding to

one side and prevent spillage.

INKUNZI IDLERS

▪ End cap/Bearing housing - 30% Glass filled Nylon

▪ Flinger - 30% Glass filled Nylon with integrated labyrinth seal.

▪ Bearings - 6205 2RS C3 (One on each side)

▪ Shaft - 25 mm steel - Tin plated.

The idler are available in 127 mm and 152 mm diameter, Series 25

The idler are available in 127 mm and 152 mm diameter, Series 25

Also Available: Anti-rollback HDPE idler

HDPE IDLERS

▪ Roller - 12mm HDPE tube

▪ Idler with gauge length of 546mm and longer will be reinforced with a 3 mm steel tube.

▪ End cap / Bearing housing - Polypropylene

▪ Flinger - HDPE with integrated labyrinth seal.

▪ Bearings - 6205 2RS C3 (One on each side)

▪ Shaft - 25 mm steel - Tin plated.

▪ SABS 0123 - The control of undesirable static electricity.

The idler are available in 127 mm and 152 mm diameter, Series 25

Also Available: Anti-rollback HDPE idler

Industry Focused Prodcuts

GARLANDS IDLERS

▪ All Nylocomp conveyor idlers can be manufactured in “Garland” style idlers as required by operations.

Industry Focused Prodcuts

IMPACT IDLERS

Impact rollers provide absorption in impact loading areas to protect the belt.

Roller diameter (mm) and (Shaft series (mm))

▪ 133 and ( 25, 30)

▪ 159 and (25, 30, 35, 40)

▪ 178 and (30, 35, 40)

▪ 219 and ( 50)

Industry Focused Prodcuts

STEEL IDLERS

▪ Nylocomp manufacture wide range of steel idlers from minimum face diameter of 50mm – 152mm, and from 20 series – 40 series.

Industry Focused Prodcuts

CONVEYOR FRAMES

Nylocomp manufactures a large variety of idler design configurations according to industry

standards such as SANS 1313, DIN or CEMA or according to customer requirements.

Nylocomp manufactures a large variety of idler design configurations according to industry

standards such as SANS 1313, DIN or CEMA or according to customer requirements.

▪ Frame configuration can be as per standards or customized to meet client specific needs.

Frames are engineered to ensure deflection and load limitation, optimal price and ease of

use.

▪ Frames are manufactured in dedicated factories, using advanced machinery such as plasma cutters, bend press brake and robotic welding machines, to ensure high quality products in large volume.

Customers have an option to chose from: Galvanized / Passivated and Painted or Zinc Plated

Industry Focused Prodcuts

ANTI-STATIC "OSTRICH BLACK" IDLERS (PATENTED)

▪ Nylocomp manufactures the Anti- Static rollers specifically for underground use in coal mines. The hull of the roller is produced from UHMWPE which is mixed with carbon thus ensuring the flow of electricity. The hull is connected to the roller shaft with a brass strip, thereby conducting the electricity to frame installation which must be grounded by law.

Industry Focused Prodcuts

CONVEYOR DROP BRACKETS

▪ 40MM DROP (1 x 90° Bend)

▪ 90MM DROP (1 x 90° Bend)

▪ 90MM DROP (2 x 45° Bends)

Industry Focused Prodcuts

SELF-TRAINING TROUGHERS

▪ Nylocomp self-training troughers are designed to automatically adjust and maintain the alignment of the conveyor belt. Nylo-Self- training troughers have a unique design that allows the idler to pivot or tilt in response to any deviation in the belt's alignment.

▪ Nylocomp offers different type of Self-Training Troughers, 3 Roll, 5 Roll Specialized, designed to fit site specific requirements.

▪ All components are laser cut ensuring that the belt training device is of highest quality.

Industry Focused Prodcuts

RETURN TRACKERS

▪ Nylocomp supplies a quality belt-centralizing return tracker that uses precision-turned C.N.C. components. Specially hardened steels, high quality bearings and high-quality components to ensure that the return tracker performs optimally over an extended period.

▪ Nylocomp offers a variety of designs of return trackers for both high and low speed conveyer belt, ranging from Flat Return Tracker, Dual Return Tracker, and V-Return Tracker.

Advantages of Using Return Trackers Supplied by Nylocomp

▪ Return tracker responds instantly to misaligning of the belt.

▪ No special changes to the structure needed.

▪ Return tracker requires little or no maintenance and fits into a standard drop bracket.

▪ Return tracker can be manufactured to suite all belt sizes.

▪ Saves money by reducing down time and reducing belt and structural damage.

Industry Focused Prodcuts

WEAR SOLUTIONS

Nylocomp supply and install a complete range of wear solutions for different application in bulk materials handling and classification applications against high- velocity impact and sliding abrasion.

Chutes

Chutes  Bins and Hoppers

Bins and Hoppers

▪ Pipes

▪ Cyclones

▪ Conveyor Belt Skirting Tipper Trucks

▪ Excavators

Advantages of Using Return Trackers Supplied by Nylocomp

▪ UHMWPE “Yiga-P® “Liners (Patented)

▪ Polyurethane Liners

▪ Rubber wear linings

▪ Ceramic Wear linings

▪ Composite Wear Liners

▪ Profiles Wear liners

▪ Sheet Liners with Steel Backing and with No steel Backing

Industry Focused Prodcuts

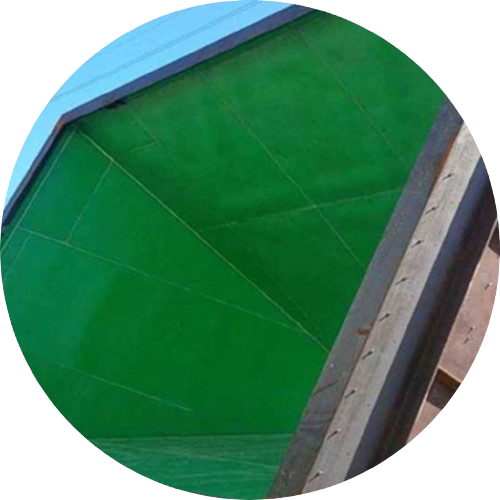

Yiga-P® LINERS

Advantages of Using YIGA-P LINERS Supplied by Nylocomp

▪ Lighter than steel liners

▪ Easier to handle and install

▪ Safer to handle

▪ Reduction of impact forces into structures and equipment

▪ Reduction in movement and vibration of building structure

▪ Reduction in noise levels

▪ Reduction in carry-back materials

▪ Less or no contamination of product with iron

Unleashing the Power of Our Field Services

Our Services

Our service starts with understanding the root cause of your conveyor problems, and what it is that you want to achieve, based on your production targets, costs savings, and safety, then Nylocomp can offer a full range of solutions for your problems. Nylocomp field service offer following service on site: